In today’s business landscape, efficient supply chain management is critical for success, regardless of the sector or size of the business. In optimising logistics operations to meet the ever-growing demands of modern commerce, warehouse automation is playing an increasingly important role. This blog will explore the ins and outs of warehouse automation, its benefits, and how businesses can implement these systems to gain a competitive edge.

What is Warehouse Automation?

Warehouse automation involves integrating technology to perform tasks traditionally handled by human workers. This encompasses a wide range of software and hardware solutions that streamline processes, improve accuracy, and enhance overall efficiency within a warehouse setting.

The primary objectives of automation are to increase productivity, reduce costs, minimise errors, and improve safety. By implementing automated warehouse systems, businesses can potentially significantly improve their operational efficiency and competitiveness.

Warehouse Automation Software and Hardware Solutions

A variety of software and hardware solutions drive warehouse automation. These technologies work together to streamline workflows and optimise warehouse operations.

Here are a few examples of warehouse automation software solutions:

- Warehouse Management Systems (WMS): These systems act as the central brain of a warehouse, managing and optimising core processes such as inventory control, order fulfilment, and labour management. WMS software can provide visibility into inventory levels, enabling efficient tracking of stock movement and optimisation of storage locations.

- Transportation Management Systems (TMS): These systems focus on optimising the movement of goods, both inbound and outbound. TMS software helps businesses plan transportation routes, manage carriers, track shipments, and optimise freight costs.

- Supply Chain Execution Systems: These comprehensive systems orchestrate various supply chain activities, including warehouse operations, transportation, and order management. They provide end-to-end visibility and control over the supply chain.

Along with software, specialised hardware is needed to automate tasks and processes within the warehouse. Here are common examples of the types of hardware components that enable and support warehouse automation:

- Barcode Scanners and RFID Readers: These devices automate the capture and tracking of product information. Barcode scanners read barcodes on products, while RFID readers utilise radio waves to identify and track tagged items, enabling real-time visibility and accurate inventory data.

- Conveyors and Sortation Systems: These systems automate the movement of goods within the warehouse, efficiently transporting items between different areas such as receiving, storage, picking, and packing. They help to speed up operations and reduce manual handling.

- Automated Guided Vehicles (AGVs) and Robots: AGVs are driverless vehicles that move materials around the warehouse, while robots can perform tasks such as picking, packing, and palletising. These technologies automate repetitive and labour-intensive tasks, improving efficiency and reducing human error.

Key Functions of Warehouse Automation

Depending on the type of automation software and hardware deployed, warehouse automation can impact various key functions, namely:

1. Inventory Management

Automation enables accurate tracking of inventory levels, monitoring stock movement, and optimising storage locations. This granular level of control helps to minimise stockouts and overstocking, ensuring that products are available at the right time and reducing the risk of obsolete stock or missed sales opportunities. By automating these processes, businesses can free up time and resources to focus on more impactful core business activities.

2. Order Management

Automated systems streamline order processing, picking, packing, and shipping, leading to faster fulfilment times and improved order accuracy. Additionally, orders can be automatically routed to the optimal picking location, and automated packing systems can ensure that goods are packed securely and efficiently.

3. Quality Control

Automated warehouse systems can be integrated with quality control processes to perform checks and identify defects, ensuring that products meet quality standards and comply with industry regulations. This is especially beneficial for sectors with high quality standards and strict regulatory requirements, such as pharmaceuticals, food and beverage, electronics, and automotive. This can involve automated inspection systems, image recognition technology, and other advanced methods.

4. Real-Time Data and Analytics

Warehouse automation systems generate a wealth of real-time data on warehouse performance, enabling data-driven decisions and continuous process optimisation. This data can be used to identify bottlenecks, track key performance indicators (KPIs), and make informed decisions to improve efficiency and productivity.

Benefits of Warehouse Automation

Warehouse automation has many advantages for businesses looking to optimise their operations:

1. Enhanced Efficiency & Accuracy

Warehouse automation minimises human error in tasks like picking, packing, and data entry, leading to improved accuracy and faster processing times. It streamlines workflows, reduces bottlenecks, and increases overall throughput. This allows businesses to process more orders with greater accuracy, leading to improved customer satisfaction.

2. Cost Reduction

Automation leads to significant cost savings through reduced labour costs, lower error rates, and optimised resource utilisation. By automating repetitive and labour-intensive tasks, businesses can redeploy their workforce to higher-value activities that require human skills and expertise, such as customer service, problem-solving, and strategic planning.

Additionally, warehouse automation plays a crucial role in reducing theft, damage, and loss of goods by enhancing security and improving inventory accuracy. Automated warehouse systems can track goods throughout the warehouse, reducing the risk of misplacement or theft. While there is a cost of warehouse automation to consider, the long-term return on investment makes it a financially sound decision for businesses seeking to improve their bottom line. The initial investment can be offset by ongoing savings in labour, reduced errors, and improved efficiency, ultimately leading to a positive impact on profitability.

3. Enhanced Financial Visibility

Automation provides real-time data and analytics for better financial tracking and forecasting. This visibility improves budgeting, inventory control, warehouse automation, and overall financial management. By having a clear picture of warehouse performance, businesses can make informed decisions to optimise their financial resources.

Embrace the Future of Automation with Halcon Primo Logistics

The future of warehousing lies in leveraging technology to unlock the full benefits and advantages of automation, creating smarter, more efficient, and more responsive operations. Halcon Primo Logistics, a leading logistics company in Singapore, is committed to innovation and providing cutting-edge logistics solutions.

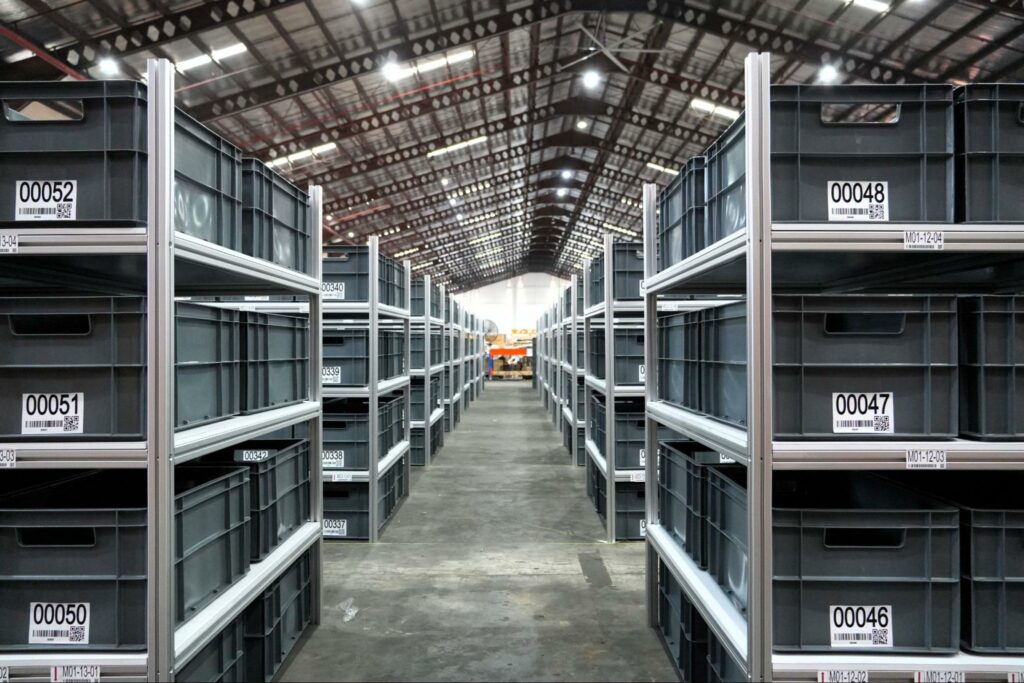

To further enhance our capabilities and service offerings, we are currently integrating an Automated Storage and Retrieval System (ASRS) within our existing bonded warehouse at Toh Guan. This advanced system will optimise space utilisation and significantly improve the speed and accuracy of our storage and retrieval processes. By incorporating this state-of-the-art technology, we are reinforcing our commitment to providing our clients with the most efficient and reliable logistics solutions available.

By partnering with Halcon Primo Logistics, businesses can leverage the latest warehouse automation technologies to optimise their supply chains and achieve their business goals. Contact Halcon Primo Logistics today to find out more about our efficient warehouse storage solutions to streamline your operations.